Capabilities

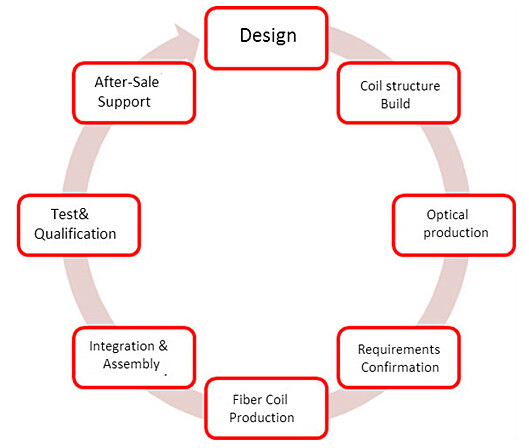

Design

We have a highly skilled, experienced and innovative design capability, unrivalled among medium sized Korea companies involved in precision optics / opto-mechanics. Our team has extensive experience in coil winding service and Integrated optic chips design to full military specifications. Our design capability encompasses optics, mechanics, and, through specialist partners, electronics and software, enabling us to undertake full responsibility for total solution design for complex, integrated assemblies. We are equally comfortable undertaking all of the work ourselves, or in working closely with the Client's own engineering team.

Our design team uses industry standard CAD tools - ZEMAX for optical design, SolidWorks for mechanical design and Essential Macleod for the coil winding service.

Coil structure Build

Many projects require us to build coil structure for testing and evaluation prior to a decision on production manufacture. Again, we are always pleased to actively support the Client's development programme, and to offer our knowledge and experience in the quest for design improvements that enable the coil to suit for the whole system for your optical gyro system.

Production Manufacture

When a design is approved for production manufacture, we will immediately assign a Production Engineer to manage the transition. His responsibility is to develop the most efficient production process, including the design and supply of tooling, documentation, test procedures, etc. Often, it will encompass design enhancements that build upon the coil winding structure. Our procurement team will set about acquiring all necessary materials, sourcing globally, including any specialist components or processes that are outsourced. The management team will schedule the production run once there is a full list of availability.

The whole manufacturing process is managed through an ERP application, and subject to the rigours of our accredited ISO 9001:2008 Quality Management System.

We take total responsibility for the full integration of our own fiber optic gyro system. We have a one week testing time in our testing center in Harbin. We are experienced in setting up production lines for fiber optic gyro systems, taking all of the internal optical and mechanical components together with third party elements we have in store, and integrating, fully assembling and testing them to guarantee the quality of fiber coil.

Test & Measurement

We are particularly proud to have comprehensive test and measurement capabilities within the Company, including high and low temperature test facilities. Within our extensive test laboratory, not only do we have high and low temperature test stations, perhaps more importantly we also have the skills and experience to test the PER value.Further testing is available to cover electronics, humidity, salt, temperature, etc. Full vibration and shock testing is undertaken when required at a local test facility.

All production output is subject to stringent final test procedures to ensure that shipped product meets or exceeds the required specification.

After Sale Support

We believe that it is important to offer ongoing support and maintenance services for the coil and all products that we deliver to our Clients. We regularly provide full life support for our manufacturing output, initially under agreed warranties and thereafter on a contracted or chargeable basis. It is common for us to provide refurbishment and upgrade programmes, and indeed we undertake some refurbishment work for systems that originated elsewhere. We maintain all tooling for in-house projects in case of later need.

© FOGphotonics, inc. | Company | Products | Technoloy | Contact us